XerxesDGreat

New elf

- Joined

- Dec 26, 2020

- Messages

- 15

I'm putting together a buy list for my display, but am running up against a wall when it comes to the physical power injection wire and, more to the point, connections. The layout I have planned is 5V, ~6000 pixels, running off Falcon F4V3 and two receivers. Based on the power requirements, 3 power supplies seem to be okay, and I've separated up the props into 24 distinct power injection runs, ~300 pixels per run.

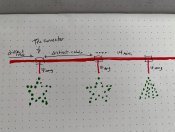

Based on this, I should be using 14awg wire, especially with some of the longer power runs (up to 70' or 20 meters). Since I'm powering multiple props off some of these runs, I'll have several branches off the main power injection line; I drew up a crude mock of what I'm talking about. Ideally, I'd like to have connections which are able to be disconnected rather than something like scotch locks, yet I haven't found any tees which would work with 14awg to keep that main line at the bigger wire size.

What are you all using for this, or am I just missing something here?

Based on this, I should be using 14awg wire, especially with some of the longer power runs (up to 70' or 20 meters). Since I'm powering multiple props off some of these runs, I'll have several branches off the main power injection line; I drew up a crude mock of what I'm talking about. Ideally, I'd like to have connections which are able to be disconnected rather than something like scotch locks, yet I haven't found any tees which would work with 14awg to keep that main line at the bigger wire size.

What are you all using for this, or am I just missing something here?