Kent

Full time elf

- Joined

- Nov 21, 2020

- Messages

- 103

I became quite interested in the GS8202 after having been originally motivated by this thread.

Now that it's really becoming urgent to get my pixel order in for 2022, I made the time to compare the sample GS8208 purchased earlier this year from Shenzhen Shiji Lighting with the 5V WS2811 purchased from Ray Wu and used in my display last year.

Google photo album

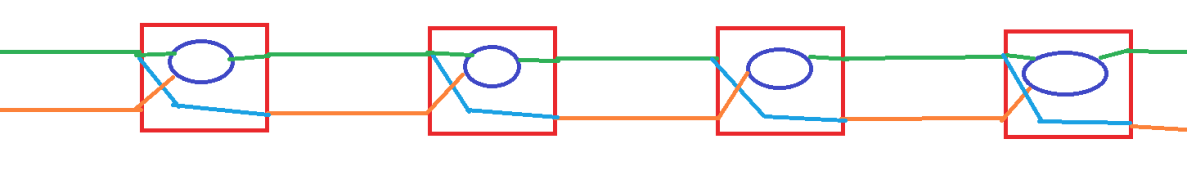

This shows the test setup used to compare the WS2811 5v (left) and GS8202 12v (right) pixels, measuring current, voltage drop, and brightness for 1, 2, and 3 colours. Single colour tests were green. Dual colour tests were red + blue. This was for consistent results as red and blue are swapped between the two strings. Each string has 50 nodes.

Associated spreadsheet with all of the interesting information

Voltage drop effects for white @ 100%:

WS2811 5v: To my eyes, the LEDs started to dim at 4.5v. From here they dimmed more dramatically and moved to a warmer colour.

GS8208 12v: There was no visible difference all the way down until 9.5v. From here they dimmed, but maintained the colour temperature. Interestingly, when set to green only, I could drop the voltage all the way to 6v before noticing any change at all.

The first photo shows the test setup. At the end of testing I randomly went back and re-ran some of the earlier tests to ensure the same current, voltage, and brightness values were obtained. Swapping the meters around gave results within 10mV of each other, and when measuring Vin at the bench supply terminals, I recorded 4.94V and 12.06V respectively.

The video shows the power up behaviour, and what happens when adding and removing power from the Quinled Dig Uno board. You'll notice that the GS8208 turn off shortly after removing power from the Quinled Dig Uno, whereas WS2811 maintain the last value sent out. When I applied power a second time, the Quinled board didn't start up correctly. Interestingly this made the GS8208 start a test mode where it cycles between R,G,B. After another power cycle the Quinled board starts up OK and everything goes back to normal. I had the board set to turn the LEDs on at 50% brightness.

The gamma correction built in to the GS8202 means that 50% brightness on the GS8208 is roughly equivalent to 25% brightness on the WS2811. Because of this, I wanted to grab some brightness measurements to compare the power draw per lumen. Whilst not a very scientific setup, I believe the values are good enough to give a bit of a comparison. The third photo shows my best effort to get consistent measurements between the two, with 23 nodes each. The light meter was a $50 cheapie off eBay, and when taking the measurements I had the room dark and only the relevant set of pixels turned on. Whilst it can't be seen in the photo, I had a reference line ~35cm from the LEDs. When taking measurements, I'd move the sensor around and recorded the maximum value.

I've drawn the following conclusions from my testing regarding the GS8208 (with respect to my other preferred option of 5v WS2811):

Pros:

Now that it's really becoming urgent to get my pixel order in for 2022, I made the time to compare the sample GS8208 purchased earlier this year from Shenzhen Shiji Lighting with the 5V WS2811 purchased from Ray Wu and used in my display last year.

Google photo album

This shows the test setup used to compare the WS2811 5v (left) and GS8202 12v (right) pixels, measuring current, voltage drop, and brightness for 1, 2, and 3 colours. Single colour tests were green. Dual colour tests were red + blue. This was for consistent results as red and blue are swapped between the two strings. Each string has 50 nodes.

Associated spreadsheet with all of the interesting information

Voltage drop effects for white @ 100%:

WS2811 5v: To my eyes, the LEDs started to dim at 4.5v. From here they dimmed more dramatically and moved to a warmer colour.

GS8208 12v: There was no visible difference all the way down until 9.5v. From here they dimmed, but maintained the colour temperature. Interestingly, when set to green only, I could drop the voltage all the way to 6v before noticing any change at all.

The first photo shows the test setup. At the end of testing I randomly went back and re-ran some of the earlier tests to ensure the same current, voltage, and brightness values were obtained. Swapping the meters around gave results within 10mV of each other, and when measuring Vin at the bench supply terminals, I recorded 4.94V and 12.06V respectively.

The video shows the power up behaviour, and what happens when adding and removing power from the Quinled Dig Uno board. You'll notice that the GS8208 turn off shortly after removing power from the Quinled Dig Uno, whereas WS2811 maintain the last value sent out. When I applied power a second time, the Quinled board didn't start up correctly. Interestingly this made the GS8208 start a test mode where it cycles between R,G,B. After another power cycle the Quinled board starts up OK and everything goes back to normal. I had the board set to turn the LEDs on at 50% brightness.

The gamma correction built in to the GS8202 means that 50% brightness on the GS8208 is roughly equivalent to 25% brightness on the WS2811. Because of this, I wanted to grab some brightness measurements to compare the power draw per lumen. Whilst not a very scientific setup, I believe the values are good enough to give a bit of a comparison. The third photo shows my best effort to get consistent measurements between the two, with 23 nodes each. The light meter was a $50 cheapie off eBay, and when taking the measurements I had the room dark and only the relevant set of pixels turned on. Whilst it can't be seen in the photo, I had a reference line ~35cm from the LEDs. When taking measurements, I'd move the sensor around and recorded the maximum value.

I've drawn the following conclusions from my testing regarding the GS8208 (with respect to my other preferred option of 5v WS2811):

Pros:

- Show can withstand single pixel failures due to the backup data line

- Better consistency between brightness steps, particularly due to fact I limit brightness to ~50%, however the real world impact may be debatable

- Lower peak power draw at typical max show brightness (For white GS8208 only uses 5.4W to produce 270 lux (75%), whilst WS2811 used 6W to produce 248 lux (50%))

- Significantly less power injection (several hundreds of pixels with no noticeable colour change)

- Significantly higher idle power (~158W vs ~24W for my ~6000 pixel display)

- Limited vendors