Hey everyone!

I have all my supplies and am doing a test run in my bonus room before venturing outside.

I am mounting aluminum channel and putting in WS2812B 5v LED strips (30 LED/meter) and using a small 22 gauge wire for power injection. That gauge wire I know could be bigger, but nothing will work inside this channel. Space is maximized.

I am running into a dilemma:

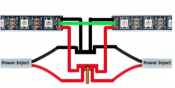

What is the best way to solder 2 LED strips together along with power injection? Does anyone have any reference pictures of what they did? I have the drawing of how I need to wire it, but if I did it the way I was going to you'll see a gap into between the strips and I want to be near seamless as possible.

I have all my supplies and am doing a test run in my bonus room before venturing outside.

I am mounting aluminum channel and putting in WS2812B 5v LED strips (30 LED/meter) and using a small 22 gauge wire for power injection. That gauge wire I know could be bigger, but nothing will work inside this channel. Space is maximized.

I am running into a dilemma:

What is the best way to solder 2 LED strips together along with power injection? Does anyone have any reference pictures of what they did? I have the drawing of how I need to wire it, but if I did it the way I was going to you'll see a gap into between the strips and I want to be near seamless as possible.