orchidman33

Full time elf

- Joined

- Jan 14, 2019

- Messages

- 125

I have been waching this thread with interest.

Question, - if you are using 12V strip is your power supply 12V Dc or 5V as per your labeled photo.

Question/ observation. You are using a linking cable between strips that has Black, Green/yellow and then another Black,. Have you Checked that you have not accidently crossed the two black wires at one end.

As for using data cable (use patch leads or Stranded cable, NOT solid core) , I am using Patch leads here 3 cores for V+, 4 cores for 0V and one for data. running a 5m 12V strip @ 30LED or 10 drivers per meter at 20% brilliance I am going 15+ meters from the power supply, no problem.

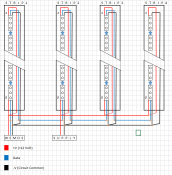

I also think that your programed pattern will not display as you want. This is due to your display is like having 4 x 2 meter strips side by side -NOT just one straight line .

Hope this gives some ideals to your issue.

Question, - if you are using 12V strip is your power supply 12V Dc or 5V as per your labeled photo.

Question/ observation. You are using a linking cable between strips that has Black, Green/yellow and then another Black,. Have you Checked that you have not accidently crossed the two black wires at one end.

As for using data cable (use patch leads or Stranded cable, NOT solid core) , I am using Patch leads here 3 cores for V+, 4 cores for 0V and one for data. running a 5m 12V strip @ 30LED or 10 drivers per meter at 20% brilliance I am going 15+ meters from the power supply, no problem.

I also think that your programed pattern will not display as you want. This is due to your display is like having 4 x 2 meter strips side by side -NOT just one straight line .

Hope this gives some ideals to your issue.