Baron

Apprentice elf

- Joined

- Dec 15, 2020

- Messages

- 62

Hello... 2 quick questions about the Gilbert Engineering Snowflake XLS450. This is my 2nd year doing a show and still am no expert so I thought I would get some help here. I recently purchased 3 of the large snowflakes and need some help if anyone has these...

Thanks for your help.

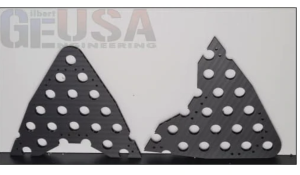

- Question 1: Black Shark Fin - in my box of 3 snowflakes I received these. I am unsure what these are can anyone help to direct me what the purpose of these are?

- Question 2: Any recommendations on how I should run power injection, data? If my controller is no more than 10 feet away, I was thinking about running 1 data and multiple power injections. I just do not know how many pixels can run off of 1 port on an F16v3 and if that would work. Any help would be great... if you have this model I would love to know how you ran it and where you placed your power injections. Why recreate the wheel if you did it right...

Thanks for your help.