Hi, Have tried unsuccessfully to hot glue a rectangular magnet to the conduit clip, without much success. At first was using bosses craft glue gun and the glue she had, but no success.

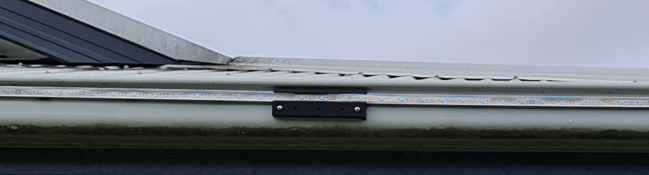

In fact, the 4 magnets/clips evenly spaced along a 1200mm piece of conduit fixed to the bottom of a clean gutter would not hold, at first OK then one of the clips would slowly peel away from the magnet and the lot comes down. Leaving 3 magnets attached to the gutter and the clips on the conduit on terra ferma.

So bought a De Walt hot glue gun and some new glue sticks (Stanley 12mm) and repeated the process. still failure.

Any suggestions have tried roughing the magnet with a bastard file, heating the magnet before glueing; these magnets are from the big chinese superstore so maybe thats the problem.

Burto

In fact, the 4 magnets/clips evenly spaced along a 1200mm piece of conduit fixed to the bottom of a clean gutter would not hold, at first OK then one of the clips would slowly peel away from the magnet and the lot comes down. Leaving 3 magnets attached to the gutter and the clips on the conduit on terra ferma.

So bought a De Walt hot glue gun and some new glue sticks (Stanley 12mm) and repeated the process. still failure.

Any suggestions have tried roughing the magnet with a bastard file, heating the magnet before glueing; these magnets are from the big chinese superstore so maybe thats the problem.

Burto