bert-nc

Apprentice elf

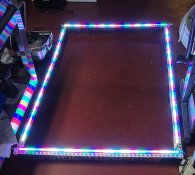

Was hoping to add some vertical effects to my display for 2025

and was thinking about making window frames to mount pixels to.

Watched a bunch of you tube videos and tried drilling holes into pvc pipe.

That did not work as well as I was hoping.

Would like to know what method you might be using.

Methods you may have tried that did not work as hoped.

Ideas you may be thinking about trying for 2025 display.

Bert-nc

and was thinking about making window frames to mount pixels to.

Watched a bunch of you tube videos and tried drilling holes into pvc pipe.

That did not work as well as I was hoping.

Would like to know what method you might be using.

Methods you may have tried that did not work as hoped.

Ideas you may be thinking about trying for 2025 display.

Bert-nc