Mike

CLAP infected!

This should go without saying it: Please do this without the controller plugged in.

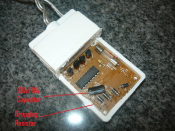

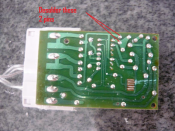

This is what I have done to make some of my 8 function controllers have a memory so I don't need to reset them

every night. Its cheap to do and simple. Parts for this are available easily and should cost about $1- $1.50

It involves changing the capacitor in the controller to a larger one that holds charge longer.

You will need:

This may not be good for computer controlled lights. Sometimes up to 20 secs delay

This has worked for all my controllers , but I cant guarantee it it will work on yours. Should work on most though

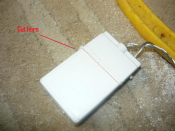

Step 1: Cut the case open With a hacksaw

Cut the case following the lines around the controller as shown in the photo. They are glued shut.

Don't try to pry them open with a screwdriver! It will slip and stab you in the hand. Trust me it doesn't work.

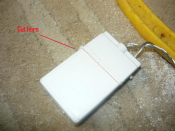

Now flip the case onto the side without the button on it (the back side) and cut along the the line as shown

in the picture. Be careful you don't go too far and hit the board or its components

Continued next post..........

This is what I have done to make some of my 8 function controllers have a memory so I don't need to reset them

every night. Its cheap to do and simple. Parts for this are available easily and should cost about $1- $1.50

It involves changing the capacitor in the controller to a larger one that holds charge longer.

You will need:

- Soldering Iron

- Solder

- De soldering Braid or Sucker pen

- 1000uf 16v Electrolytic Capacitor

- Hacksaw

- Duct Tape

- 1N4148 Diode (maybe)

This may not be good for computer controlled lights. Sometimes up to 20 secs delay

This has worked for all my controllers , but I cant guarantee it it will work on yours. Should work on most though

Step 1: Cut the case open With a hacksaw

Cut the case following the lines around the controller as shown in the photo. They are glued shut.

Don't try to pry them open with a screwdriver! It will slip and stab you in the hand. Trust me it doesn't work.

Now flip the case onto the side without the button on it (the back side) and cut along the the line as shown

in the picture. Be careful you don't go too far and hit the board or its components

Continued next post..........