Hi all,

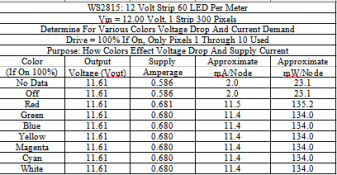

I would like to install led pixel strips in my kids room. I have 3, 5 meter strips of 12V WS2815 with 60 pixels per meter. This totals 900 12V pixels. I have a 30 Amp power supply and I'm wondering if that would be sufficient? I am using wLed, so would it be possible to use the current limiting setting if not? I'm also wondering If I can get away with injecting power at both ends of the 15 meter strip run, or if I would need to inject power in the middle as well? Thanks for any light you can shed.

I would like to install led pixel strips in my kids room. I have 3, 5 meter strips of 12V WS2815 with 60 pixels per meter. This totals 900 12V pixels. I have a 30 Amp power supply and I'm wondering if that would be sufficient? I am using wLed, so would it be possible to use the current limiting setting if not? I'm also wondering If I can get away with injecting power at both ends of the 15 meter strip run, or if I would need to inject power in the middle as well? Thanks for any light you can shed.