thewanderingpine

Senior elf

- Joined

- Mar 13, 2021

- Messages

- 530

So partially inspired by this video:

View: https://www.youtube.com/watch?v=d-t0tVdP6E0

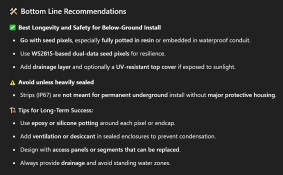

I'm thinking about doing some in/on ground permanent LED installs. I have 3 choices but I'm not really sure about longevity/water-ingress/etc.

So perhaps the choice is really between the top 2 -- and if I decide to go for white then I pick the 2805. Any thoughts on leaving LED's at/below ground level year-round? Would you go seed or strip for this?

View: https://www.youtube.com/watch?v=d-t0tVdP6E0

I'm thinking about doing some in/on ground permanent LED installs. I have 3 choices but I'm not really sure about longevity/water-ingress/etc.

- 12V Dual Data Seed pixels (probably at 30mm spacing)

- 12V WS2815 IP67 strip at 30/m

- 12V WS2805 IP67 strip

So perhaps the choice is really between the top 2 -- and if I decide to go for white then I pick the 2805. Any thoughts on leaving LED's at/below ground level year-round? Would you go seed or strip for this?