raymondclow

New elf

- Joined

- Nov 25, 2021

- Messages

- 18

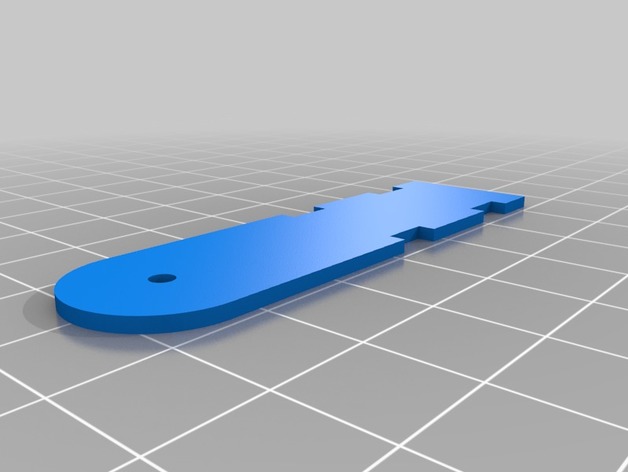

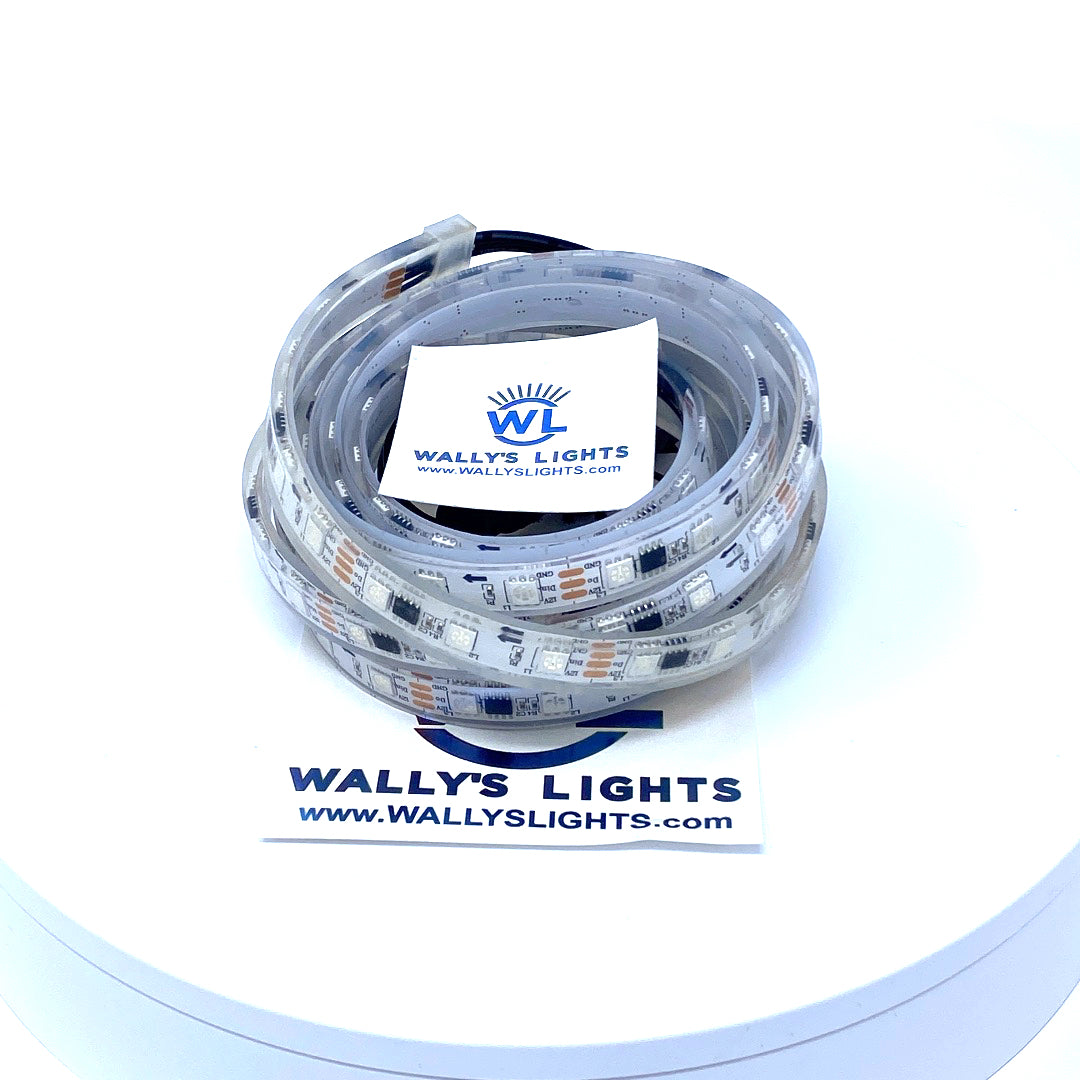

First of all thank you for anybody that stops by to give me some ideas or insight on what i can do with an issue i am having right now, I am using an led strip cut in half to make two arches, this year i bought another strip to make two more arches. Everything was running well until yesterday i notice some flickering and one completely out, after breaking my head trying to figure out the issue i noticed that at the end of each strip, the constant bending started to mess up the inside of the strip, i had to cut and solder the pigtails again to make it work. Is there a way to keep them from bending to the point they start to break? I 3d printed a model someone posted to use at the end of the strip but it doesnt fit with the ray wu pigtails, this model is more for the original connectors they come with. Any thoughts? thanks.