cray-

New elf

- Joined

- Oct 9, 2021

- Messages

- 6

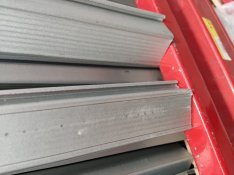

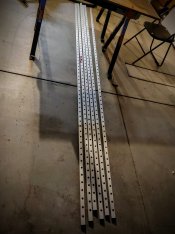

Heya, as mentioned in my intro thread, just bought myself 500x pixels with the idea of maybe making them permanent on the front of my house and roofline. So had a poke around Bunnies this arvo and came across this stuff. It's a wall/drop ceiling system made by KNAUF with various profiles available. The J and U shaped stuff comes in two depths and at between $7-$10 for a 3.6m length the price is certainly right. Bluescope has instructions on their site about how to wash and paint it, looks pretty straight forward: http://www.bluescopesteel.com.au/howto/painting-zincalume

"hahahahah have fun drilling holes in that stuff buddy!" I hear you all saying? Well say hello to my not-so-little friend!

(OK that one is not mine, I just found an equivalent machine on google images, but anyway)

I happen to operate a 1.8m x 3.6m waterjet in a signage fabrication shop as a day job. It cuts through solid steel like the proverbial hot knife through butter. A few 12mm holes in a bit of tin will only take minutes.

What do ya'll think?

"hahahahah have fun drilling holes in that stuff buddy!" I hear you all saying? Well say hello to my not-so-little friend!

(OK that one is not mine, I just found an equivalent machine on google images, but anyway)

I happen to operate a 1.8m x 3.6m waterjet in a signage fabrication shop as a day job. It cuts through solid steel like the proverbial hot knife through butter. A few 12mm holes in a bit of tin will only take minutes.

What do ya'll think?