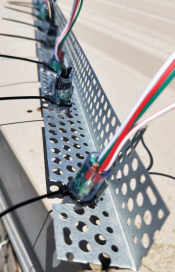

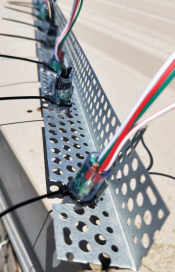

Hi all trying a couple of different securing methods for pixels on my roof.

First is cable tide to the top of a plaster corner straight down flat, but when on the steel roof it would have a the effect of becoming the same temp in 45 degree heat, the roof would be double that.

Or the second where i have cut notches and put the pixels in, less contact to the pixel.

I guess with both i could put a plastic washer between them to insulate from the extreme heat of the roof.

First is cable tide to the top of a plaster corner straight down flat, but when on the steel roof it would have a the effect of becoming the same temp in 45 degree heat, the roof would be double that.

Or the second where i have cut notches and put the pixels in, less contact to the pixel.

I guess with both i could put a plastic washer between them to insulate from the extreme heat of the roof.

![20221114_224210[9283].jpg](/data/attachments/14/14898-cea2219d700e3865ba6952f601820a51.jpg)