videoman3857

Full time elf

Hi All.

With all the stuff I have to do to my light repairs and builds, babysitting the grandkids and working for a living, I have no time (or room) to remove my 3D printer from its packaging and learn how to use it.

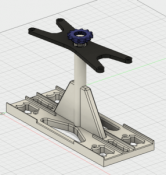

Anyone out there in 3D printing land have the time to print me up 2 Duel PSU carriages ? (payable of course)

I have the stl files in Zip format that I can supply .

Last edited: