nzlongfellow

Dennis from NZ

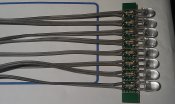

drlucas said:Yes - I'm tinning the pad on the board (both - and + sides) then heating the underside of the leg and using a pair of pliers or helping hands to get it to sit flat on the board. I am however not heating the led itself or really letting it flow onto the top of the leg. That I suspect is where much of my problems are coming from. What is the tolerance for heat on those legs...can I heat it for a good 10sec or so without damaging it?

I had the same issue where I could lift them off after soldering.

I then held the strobe in my "helping hands" by the glass with the side of the legs that face the board facing up. I then made sure I tinned the legs correctly. You do need an amount of heat to ensure they are tinned properly. I then tinned the board terminals then holding the full strip of circuit boards in my helping hands by the end pieces that will be discarded I held the strobe in place with my fingers and applied heat to the legs in turn. Got good solder flow.

I just used the resin core solder AAH suggested.

Sorry mine are all made to cannot show the process.