Hi All,

Looking at different options for wiring a large matrix, and at the same time trying to keep the weight down as much as possible. I am planning on having the garage door operational so the weight is quite important.

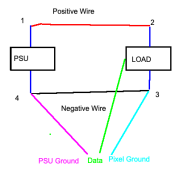

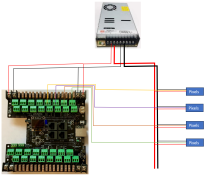

What i am looking at doing is running a power bus using larger gauge wire and then tapping into it at regular intervals by soldering in pigtails. It is looking like 16-20 channels of the below setup. I will be using a two large power supplies to run the controller. (i understand that data lines from each side of the controller will only be connected to the same PS etc)

Anyway, is there any issues with this layout? I've just received the controller so will be testing it out, but wanted to run it past the brains trust.

I was planning on using a 8core cable with one core to each set of pixels. Its looking like the maximum length from controller to pixels will be about 6-7m. I've used extension cables of that length before with good results. Running extension cables for each output will get heavy so hopefully this will work.

Thanks all

Looking at different options for wiring a large matrix, and at the same time trying to keep the weight down as much as possible. I am planning on having the garage door operational so the weight is quite important.

What i am looking at doing is running a power bus using larger gauge wire and then tapping into it at regular intervals by soldering in pigtails. It is looking like 16-20 channels of the below setup. I will be using a two large power supplies to run the controller. (i understand that data lines from each side of the controller will only be connected to the same PS etc)

Anyway, is there any issues with this layout? I've just received the controller so will be testing it out, but wanted to run it past the brains trust.

I was planning on using a 8core cable with one core to each set of pixels. Its looking like the maximum length from controller to pixels will be about 6-7m. I've used extension cables of that length before with good results. Running extension cables for each output will get heavy so hopefully this will work.

Thanks all