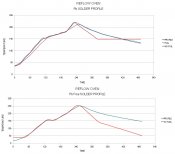

Finally got around to finishing off the reflow controller kit that I bought months ago from Sparkfun. It initially had a sluggish response, but once I covered the glass door with aluminium foil the performance improved significantly. Although I still have the original profile in Program 1, I added a Lead-free profile to Program 2.

I used the Pickit2 with the stand alone programming software to modify the EEPROM to store the new profile before programming the PIC.

I used the Pickit2 with the stand alone programming software to modify the EEPROM to store the new profile before programming the PIC.