Bird

LOR user

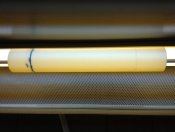

I am using "IPS Weldon #16, clear, medium bodied, solvent cement, for joining acrylic".Henedce said:I used Gorrilla grip Cyo glue with a 1 inch off cut split down the middle and wrapped around the outer to give the glue something to hold onto .

I am also using a 1" slice of tubing. However I am cutting and removing a small section of the ring so I can compess the ring and place it on the interior of the tube. I will explain my reason later "IF IT WORKS"

So far the bond is fairly strong.

Today is the 1st warm day I have had in 2 weekends to do some more work on my arch idea. Hopefully I will be able to post a 'how to' for the arch (in the arch topic section) soon.