BrianZ

Full time elf

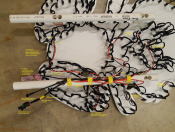

I have a quick question...can I use one 14AWG cable and a 15a fuse block to power inject at multiple points? I’ll just be splicing into the cable at different inject points instead of running multiple PI cable from the block.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Do you recommend using multiple PI lines then?You can but one needs to sub-fuse. That is each splice into the prop needs to be fused down to protect the lower current device whether it is a string, strip, or flood, etc. The reason is if something would happen to cause the prop to absorb the entire 14 AWG fused 15 Amp load the wire and/or prop would burn.

Beyond that, one would then need to evaluate voltage drop relative to cable length and current draw as should be done with any power injection cable.

For myself I have yet needed to but yes. If the voltage drop becomes too great or I would max the cable's amperage capacity I would add another power injection cable.Do you recommend using multiple PI lines then?