Up front many thanks to Mark i think that warned me to check all the seed pixels to ensure the epoxy covering was complete.

BTF-Lighting has been the place i have been buying mine from and both lots i have ordered for myself have been ip65 rated.

I have another order coming in for a friend that are classed as IP67, so be interesting to see if there is any difference.

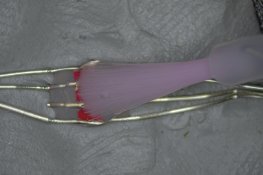

Ok so led, electronics side, this is the side that lights up

Of the hundreds i have looked at the electronics side has always been fully sealed. The cut of wires actually connect to the circuit board and i suspect these are actually 2818 dual path pixels with only a single data path used. no other reason to have the forth wire in place but cut off.

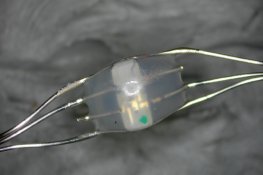

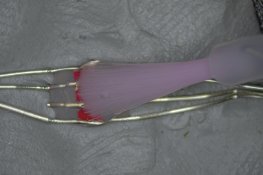

The side view of one properly encapsulated front and back. There is evidence that these are reflow soldered based on the little solder balls you typically see when all the solder paste doesn't flow together.... no big deal just interesting.

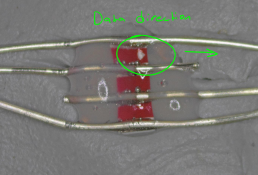

Now for some example backs were the epoxy coating is not full done.

Considering the wire seems to be enamel coated anyway this really shouldn't be an issue but if you want to be sure then grab some nail polish, fast drying and brush a bit on

I haven't tried it but a touch of hot melt glue would likely work as well.

I do think that it doesn't matter to much and only if they got submerged would you see an issue

Cheers

Phil

BTF-Lighting has been the place i have been buying mine from and both lots i have ordered for myself have been ip65 rated.

I have another order coming in for a friend that are classed as IP67, so be interesting to see if there is any difference.

Ok so led, electronics side, this is the side that lights up

Of the hundreds i have looked at the electronics side has always been fully sealed. The cut of wires actually connect to the circuit board and i suspect these are actually 2818 dual path pixels with only a single data path used. no other reason to have the forth wire in place but cut off.

The side view of one properly encapsulated front and back. There is evidence that these are reflow soldered based on the little solder balls you typically see when all the solder paste doesn't flow together.... no big deal just interesting.

Now for some example backs were the epoxy coating is not full done.

Considering the wire seems to be enamel coated anyway this really shouldn't be an issue but if you want to be sure then grab some nail polish, fast drying and brush a bit on

I haven't tried it but a touch of hot melt glue would likely work as well.

I do think that it doesn't matter to much and only if they got submerged would you see an issue

Cheers

Phil