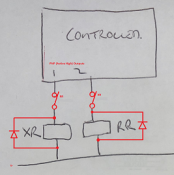

To be honest I’ll probably end up using your wiring.An yet you're not wanting to avoid a situation where 2 relays on at the same time will short the supply?

I’ll just have to source a break before make relay.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

To be honest I’ll probably end up using your wiring.An yet you're not wanting to avoid a situation where 2 relays on at the same time will short the supply?

I've not heard this term before, is this just Normally Open contacts or something different entirely?Every relay I've ever used in the last 40 years has been break before make.

You'd have to look hard to find a make before break type.

Kurt87 mentioned them early in the thread.I've not heard this term before, is this just Normally Open contacts or something different entirely?

Apologies not really necessary I think. A can of worms; perhaps.Yea sorry if I opened up a can of worms ... wasn’t my intention. just simply wanted you to be aware of the possibility of this issue when switching between positive and negative lines especially if it’s a cheap Rough as guts made relay which are not reliable and especially with a scenario where it may be making a lot of state changes where a welded contact could be possible over time

It’s all good.Yea sorry if I opened up a can of worms ... wasn’t my intention. just simply wanted you to be aware of the possibility of this issue when switching between positive and negative lines especially if it’s a cheap Rough as guts made relay which are not reliable and especially with a scenario where it may be making a lot of state changes where a welded contact could be possible over time

I would say yes, looking at @AAH op he mentions the use of DC dimmers to control a relay by sending signals of 0 and 100% value curves. Then looking at his shop he has DC Dimmer boards with ws2811 pixel data or dmx data control.Can I program a dmx relay output in a similar manner is yet to be confirmed.

Do-able this way but not really necessary as there are DMX On/Off controllers. Blue Point Engineering makes one with 10 Volt 200 mAmp outputs; intended for SSRs (solid state relay) to control 120 VAC it seems. US manufacturer I think. Would be surprised if something similar is not available in Australia.I would say yes, looking at @AAH op he mentions the use of DC dimmers to control a relay by sending signals of 0 and 100% value curves. Then looking at his shop he has DC Dimmer boards with ws2811 pixel data or dmx data control.

At this stage I just want to use a linear actuator to rotate a prop slightly. Next year maybe add a servo or stepper motor to make it travel.Do-able this way but not really necessary as there are DMX On/Off controllers. Blue Point Engineering makes one with 10 Volt 200 mAmp outputs; intended for SSRs (solid state relay) to control 120 VAC it seems. US manufacturer I think. Would be surprised if something similar is not available in Australia.

Myself, if I was thinking of this I would go proportional, along the lines of a moving head flood. Position feedback might be a bit of a challenge.