Whitey-

Apprentice elf

- Thread starter

- #76

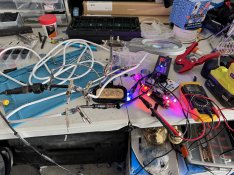

First up my arches. I actually hate them. The HDPE is great, but the feet I tweaked for my needs are awful - I suspect because I'm bad at 3D printing.

I had constant issues with snapping, sealing, and (I also hate LED strips) with poor soldering/lost pad connections. In hindsign, I also should have put a dab of glue or something on the back of the strips - I don't think it's obvious in my video (or in person for normal people), but for me the twisting in a couple of the arches was incredibly obvious and frustrating. I spent many hours trying to get these siliconed, clamped, drilled, screwed and broadly functional, and they were really held together with hopes and dreams. I originally planned 8, but scrapped down to 4 due to time constraints.

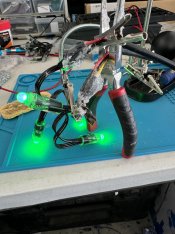

All that said, they did end up looking pretty good. Big thanks to @LawrenceDriveLights for making the point of groups of 4 - once I got to sequencing, having a group of 4 made my life so much easier!

I had constant issues with snapping, sealing, and (I also hate LED strips) with poor soldering/lost pad connections. In hindsign, I also should have put a dab of glue or something on the back of the strips - I don't think it's obvious in my video (or in person for normal people), but for me the twisting in a couple of the arches was incredibly obvious and frustrating. I spent many hours trying to get these siliconed, clamped, drilled, screwed and broadly functional, and they were really held together with hopes and dreams. I originally planned 8, but scrapped down to 4 due to time constraints.

All that said, they did end up looking pretty good. Big thanks to @LawrenceDriveLights for making the point of groups of 4 - once I got to sequencing, having a group of 4 made my life so much easier!