brando

Full time elf

Zip tied one conduit through the overflow vent, piggy backed two conduit clips for another conduit with chromatrim?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Zip tied one conduit through the overflow vent, piggy backed two conduit clips for another conduit with chromatrim?

Conduit I quickly screwed together timber scraps for the jig. 12mm forstner bit through both sides, and come back with a 16mm forstner for the back for clearance to put the pixel through

View attachment 19778View attachment 19779

That's a great idea. Love the magnet roof one too for centering.For gutters I cut 4 hole pieces of the same make-a-bracket, bent over the gutter and screwed conduit clip. Will cushion the back of the screws to reduce scratching, but these are holding up a 5m length full of pixels without bending or any issue. Gives me the clearance for the wires and control over the direction I want the pixels pointingView attachment 19775View attachment 19776View attachment 19777

So what is your source of magnets for these please ?I’ve been stuck on a best option for my ridge caps. I’m probably not the first to do this but I haven’t seen it anywhere else. This is just a piece of make-a-bracket, with magnets at centre and the outsides, screw through to a conduit clip.

Holds super strong. Now to paint it up and add heat shrink to the centre magnets. At least now my lines will be in the centre

The ones used here areSo what is your source of magnets for these please ?

Are you able to share your 3D print file please?I’m getting some brackets 3D printed to fit some rare earth magnets. Then pouring clear epoxy resin over them to seal them in and prevent scratching of roof and rust appearing.

Im printing some 3d brackets also. Interested in how you are doing the epoxy over them? I.E not too thick to reduce magnet strength. Are you doing the whole printed clip or somehow just the pockets where the mags sit in?I’m getting some brackets 3D printed to fit some rare earth magnets. Then pouring clear epoxy resin over them to seal them in and prevent scratching of roof and rust appearing.

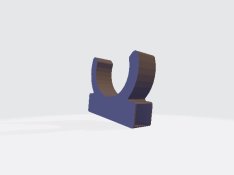

any chance you can share the file please?I thought about doing the whole clip like that and magnet in one, but prefer the cover for the magnet so it doesn't scratch the paint on my gutter and colourbond roof when moving around into position etc. My magnets don't have a screw hole either. I just designed my mount myself, took about 10 mins, and printed in PETG 0.3mm in 23mins.The clips are cheap as chips from bunnings from memory, or I can make them separate.

Also just be sure your printing the right size, he's talking inches on that link which might cause you issues, because you can't just scale it up.

if your going to go the trouble of 3D printing a clips wouldnt you be better redesign that clip to your needs ?Im printing some 3d brackets also. Interested in how you are doing the epoxy over them? I.E not too thick to reduce magnet strength. Are you doing the whole printed clip or somehow just the pockets where the mags sit in?

Ive done the heat tube, but It seems to reduce mag strength after heating (could be user).

Thank you in advance.