To be fair, this data is taken from two orders placed this year and not from earlier years.

Both sets are two 50 count strings solder joined in the middle with 140mm space to form 100 cnt strings

Set 1 - 18AWG 2818 bullet pixels

Set 2 - 20AWG 2811 bullet pixels

As the positive and negative wiring a a straight connection past each pixel you can measure the loop resistance by shorting out the far end.

The lead resistance was removed from the multimeter reading by using relative readings.

Resistance calculations are based on the data from this site: https://www.omnicalculator.com/physics/wire-resistance

Now like me you have done a double take on the measured reading and said wtf, how can 20awg be better than 18awg. Seems one is copper and the other is aluminium wires.

So not only is your resistance and hence voltage drop dependent on the wire gauge it is also dependent on the wire TYPE.

the ugly truth may well be that the 18awg pixels we buy at a small premium may be no better than a quality 20awg when considering voltage drop.

We should all ask what type of wire is being used as well as the wire size

STOP using wire gauge .... ASK for the wire strands and individual wire size

Examples and some photos.

Pixel 18 gauge = 34 strands of 0.10mm wire

Pixel 20 gauge = 21 strands of 0.10 wire

7.5A Fig8 in aus = 24 x 0.20

10A Fig8 - 32 x 020

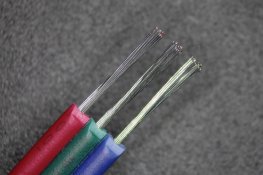

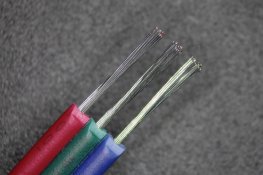

so some photos, all taken under the microscope.

Pixel 18

Pixel 20

Pixel 20 versus Pixel 18

Pixel 18 v Pixel 20 at a strand level, they are the same strand size just different counts (and types it seems)

The black is an artifact only they are all nice shiny silver

An here is Pixel 18 compared to some 24x020

Cheers

Phil

Both sets are two 50 count strings solder joined in the middle with 140mm space to form 100 cnt strings

Set 1 - 18AWG 2818 bullet pixels

Set 2 - 20AWG 2811 bullet pixels

As the positive and negative wiring a a straight connection past each pixel you can measure the loop resistance by shorting out the far end.

The lead resistance was removed from the multimeter reading by using relative readings.

Resistance calculations are based on the data from this site: https://www.omnicalculator.com/physics/wire-resistance

| Pixel WG | 18 | 20 |

| Distance Used This is the loop length of a 100 pixels at 4" spacing | 20M | 20M |

| Calculated Res - Alu | 1.985 | 3.214 |

| Calculated Res - Copper | 1.281 | 2.074 |

| Measured Resistance | 1.995 | 1.91 |

Now like me you have done a double take on the measured reading and said wtf, how can 20awg be better than 18awg. Seems one is copper and the other is aluminium wires.

So not only is your resistance and hence voltage drop dependent on the wire gauge it is also dependent on the wire TYPE.

the ugly truth may well be that the 18awg pixels we buy at a small premium may be no better than a quality 20awg when considering voltage drop.

We should all ask what type of wire is being used as well as the wire size

STOP using wire gauge .... ASK for the wire strands and individual wire size

Examples and some photos.

Pixel 18 gauge = 34 strands of 0.10mm wire

Pixel 20 gauge = 21 strands of 0.10 wire

7.5A Fig8 in aus = 24 x 0.20

10A Fig8 - 32 x 020

so some photos, all taken under the microscope.

Pixel 18

Pixel 20

Pixel 20 versus Pixel 18

Pixel 18 v Pixel 20 at a strand level, they are the same strand size just different counts (and types it seems)

The black is an artifact only they are all nice shiny silver

An here is Pixel 18 compared to some 24x020

Cheers

Phil