xarcherdrum137

New elf

- Joined

- Nov 11, 2019

- Messages

- 2

Hello all,

This is my first year getting into the hobby after a couple of years of considering it but knowing I was about to move and deciding to wait. I've done a good bit of research and feel comfortable that I know all of the major elements that I need, but the wiring to connect it all together is something I've been struggling to find a whole lot of information on. This post is primarily concerned with the termination of that wiring.

Setup:

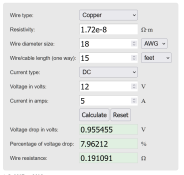

I will be starting small, and plan to drive 700 lights using a Falcon PiCap on a Raspberry Pi for the controller and the Falcon F8 distro to support power injection. From what I have gathered in my initial research, larger wire is preferred to keep voltage drops to a minimum. I'm not trying to make incredibly long runs for the power injection, but I expect the longest run from power supply to the end of the string to be ~15 feet. I was looking to use 12 AWG wire for this. However, the terminal blocks for making electrical connection on the PiCap and F8 distro support a maximum of only 18 AWG.

Question:

I am trying to figure out how to properly get my 12 AWG wire into terminal blocks meant for 18 AWG and want to know what other people are doing. I looked into ferrules but didn't see any with such a large gauge discrepancy. Do people just solder a short segment of smaller diameter wire to terminate their wire runs? Or is using 12 AWG overkill and I should just go down to 18? Or is there something else that I am missing here? How do you all wire power to your runs?

Thank you.

This is my first year getting into the hobby after a couple of years of considering it but knowing I was about to move and deciding to wait. I've done a good bit of research and feel comfortable that I know all of the major elements that I need, but the wiring to connect it all together is something I've been struggling to find a whole lot of information on. This post is primarily concerned with the termination of that wiring.

Setup:

I will be starting small, and plan to drive 700 lights using a Falcon PiCap on a Raspberry Pi for the controller and the Falcon F8 distro to support power injection. From what I have gathered in my initial research, larger wire is preferred to keep voltage drops to a minimum. I'm not trying to make incredibly long runs for the power injection, but I expect the longest run from power supply to the end of the string to be ~15 feet. I was looking to use 12 AWG wire for this. However, the terminal blocks for making electrical connection on the PiCap and F8 distro support a maximum of only 18 AWG.

Question:

I am trying to figure out how to properly get my 12 AWG wire into terminal blocks meant for 18 AWG and want to know what other people are doing. I looked into ferrules but didn't see any with such a large gauge discrepancy. Do people just solder a short segment of smaller diameter wire to terminate their wire runs? Or is using 12 AWG overkill and I should just go down to 18? Or is there something else that I am missing here? How do you all wire power to your runs?

Thank you.