Snicko

Full time elf

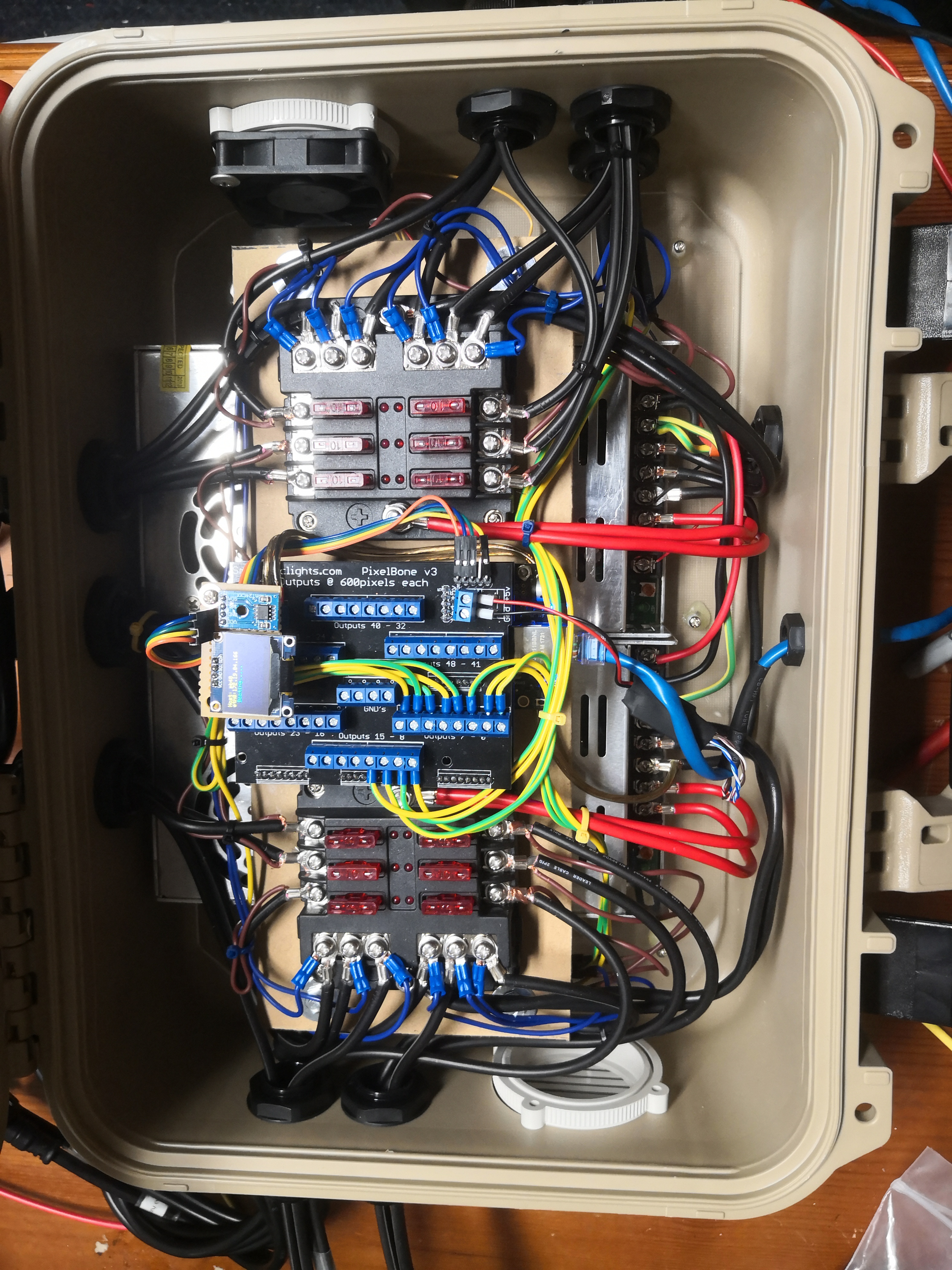

Nah they dontGood value. Potential stupid question, how do you anchor a base plate in this? Assume it doesn’t have threaded inserts like an electrical box but is there a section to insert a rivnut?

Personally id use some SS bolts thru the back into a standoff inside, then some silicon over the bolt if i went that path

Those cases are very durable, I house my drone in one.