Good point, well spotted!!It’s also worth noting that the spreadsheet included 5 power boxes - so there is likely enough amps available.

Would allow for good distribution and shorter power runs = less voltage drop.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Good point, well spotted!!It’s also worth noting that the spreadsheet included 5 power boxes - so there is likely enough amps available.

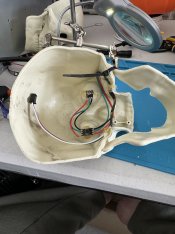

I appreciate the obvious, it's not always to meRemember the (obvious) fact that it's much easier to paint the prop while it's empty of pixels. So if you're going to do it -- you need to paint first.

Thank you, I'll go buy some once my coro ships. Apparently my Light It Up order is already with Auspost - Paul doesn't mess around!This paint and prime stuff is the best. Water based paint will scratch off PVC easily, even with a sand. Oil based spray such as the cheap “fiddly bits” cans ($5 ea) is good but still scratches a bit. But this stuff is like multiple coats in one. You pay for it though, and they don’t have “hide in the garden green”!

Thank you! I realised this by accident whilst triple checking my order this morning and ordered the LRS-450-5 ones from Light It Up. I'm glad to hear you say that - I was sure I'd seen them say 70A when looking previously (on AliExpress) and seeing 60A today confused me! I did grab one LRS-350-5 as a spare though.One other thing to note as well is that there's a huge mistake made as well in the spreadsheet above - which is the assumption that a Meanwell LRS-350 is a 350W power supply.

That's just the model range, which is typically 350W at the higher voltages. But at 5V, it's only 60A, if you look at the data sheet.

The AliExpress Chinese no-name ones will state they are a 70A PSU explicitly. That said, whether they perform that high is another matter.

Yes, this is my rationale. I'd like to spread them around enough so power is never that far away, given I'm running 5V. That said, I think I'm going to be terminating a fair whack of 18AWG myselfWould allow for good distribution and shorter power runs = less voltage drop.